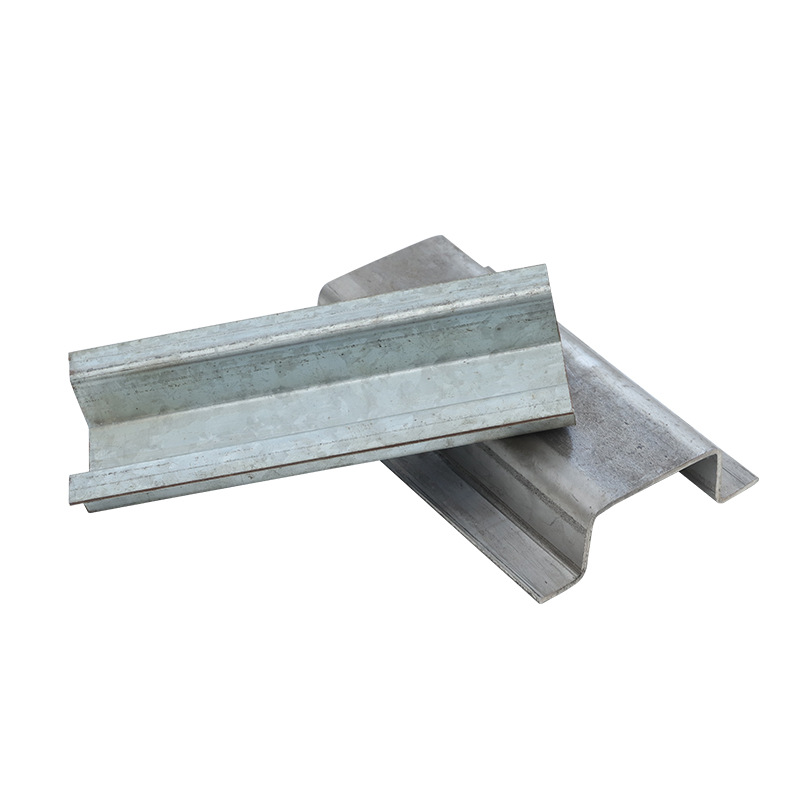

Omega Steel Section

|

Product Name |

Omega Special Shaped Steel Section |

|

Place of Origin |

Tianjin, China(Mainland) |

|

Type |

Cold Formed Profile Steel |

|

Shape |

Customized |

|

Material |

195/Q235/Q345/304/316L/Other metal materials |

|

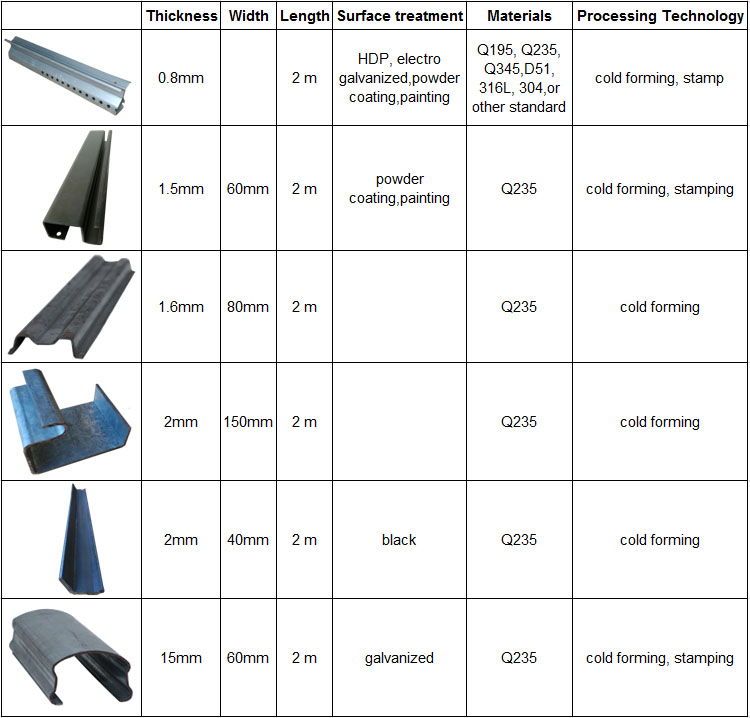

Thickness |

0.5-6mm |

|

Width |

550mm |

|

Length |

0.5-12meters |

|

Surface Treatment |

HDG, Pre-galvanized, Powder Coating, Electro-galvanized |

|

Processing Technology |

Cold Forming |

|

Application |

Construction |

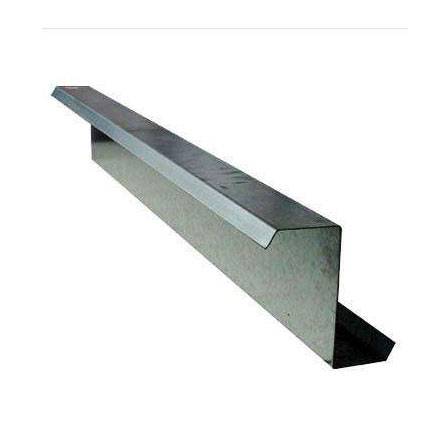

Omega Special Shaped Steel Section another way to call it hat channel.Hat channel is a hat-shaped framing member used when furring concrete, masonry walls, and ceilings. It provides a non-combustible solution for leveling uneven surfaces and comes in a variety of depths, gauges, and widths.

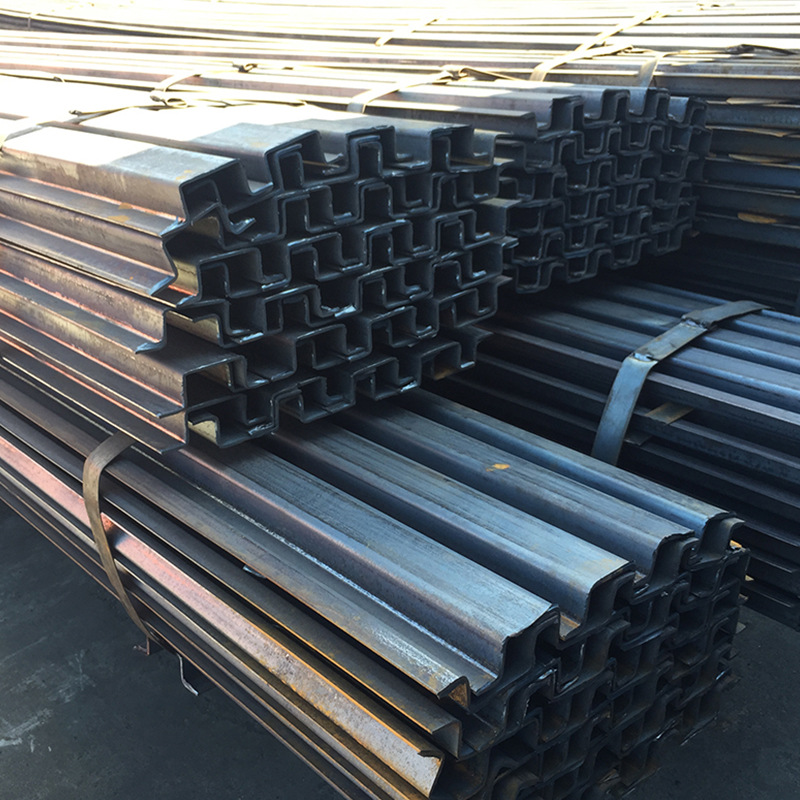

Omega Steel Purlin, is perfect for leveling walls and uneven surfaces. You commonly see it used in concrete walls and masonry walls in both commercial and residential construction.The name hat channel comes from the shape of the channel. The profile resembles the shape of a top hat.Hat channels are unique because of their hat-shaped design. The design and profile of the hat channel help give it strength.

Omega Steel Section are used in a variety of ways in both commercial and residential construction.Whether it’s at the underside of the building structure, basement renovations, or furring concrete interior walls, hat channels are incredibly versatile.Depending on the layers of drywall added to the hat channel, you can get additional acoustical performance and high STC ratings from an existing wall by adding hat channel.

Installing hat channels involves the use of concrete screws or fasteners, spaced roughly 12 to 24 inches apart.The first two fasteners are on either side of the channel. The screws can also connect directly to any wall studs.Hat channels are typically used on hardened concrete or mason walls.