Are you looking for a reliable and efficient solution for your steel structure project? Look no further than Z-Steel, the ultimate cold-formed thin-wall steel of superior quality and performance. With its adjustable size and excellent compressive strength, Z-Steel is the first choice for a wide range of applications in various industries. Whether you are working on automobiles, rail vehicles or building structures, Z-Steel is ideal to guarantee the best results.

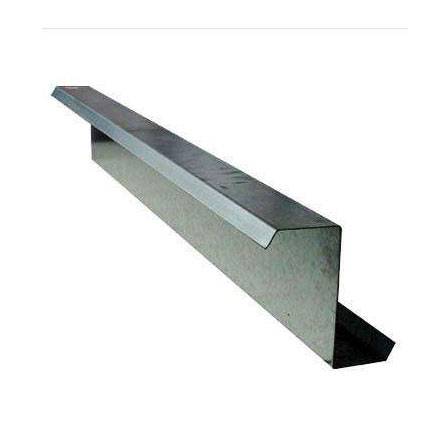

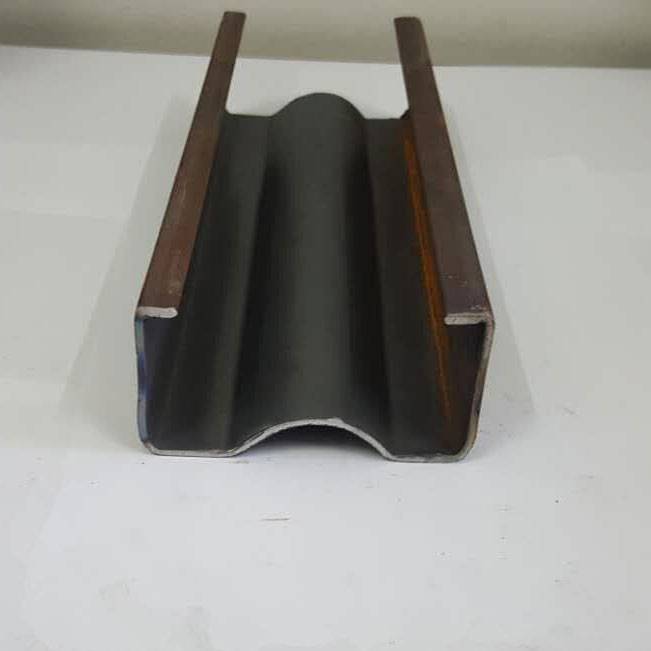

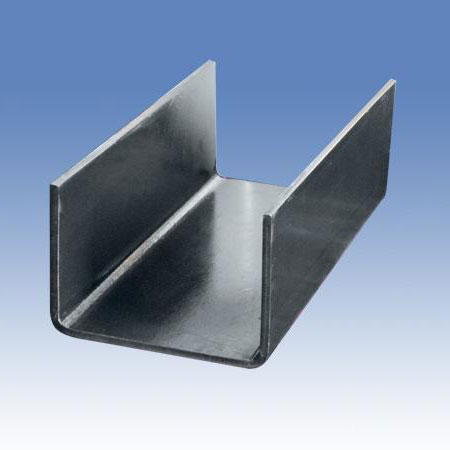

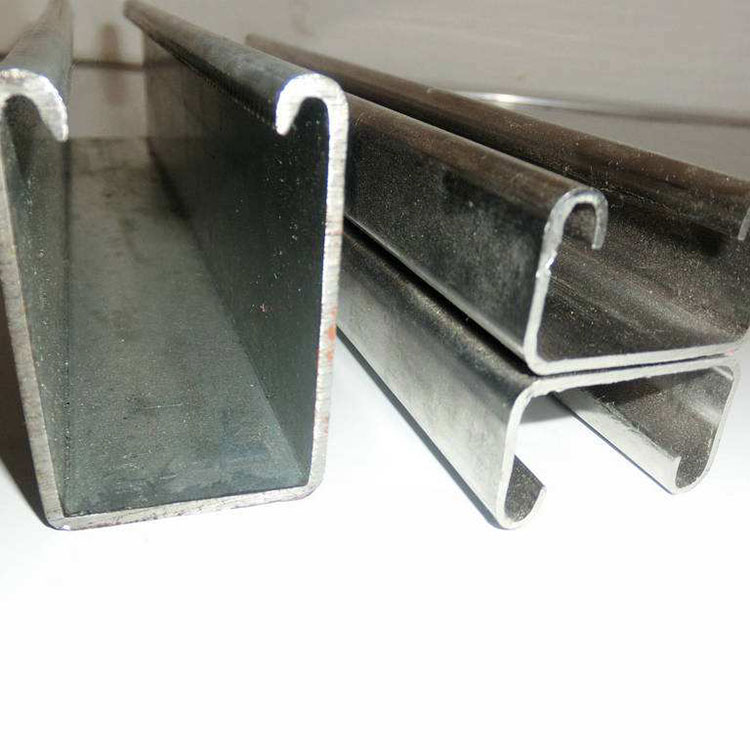

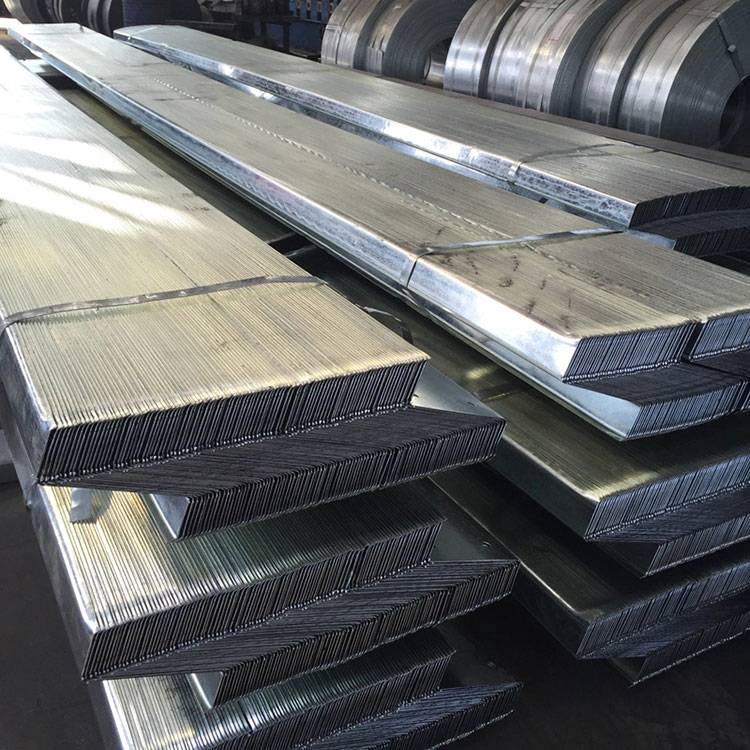

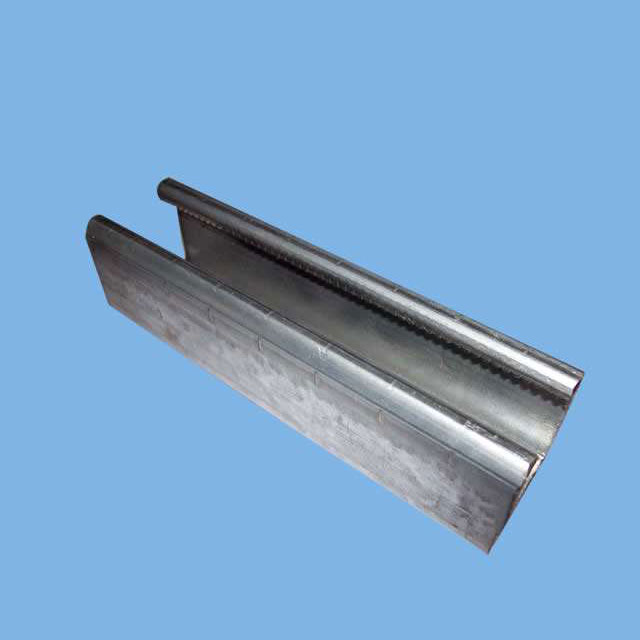

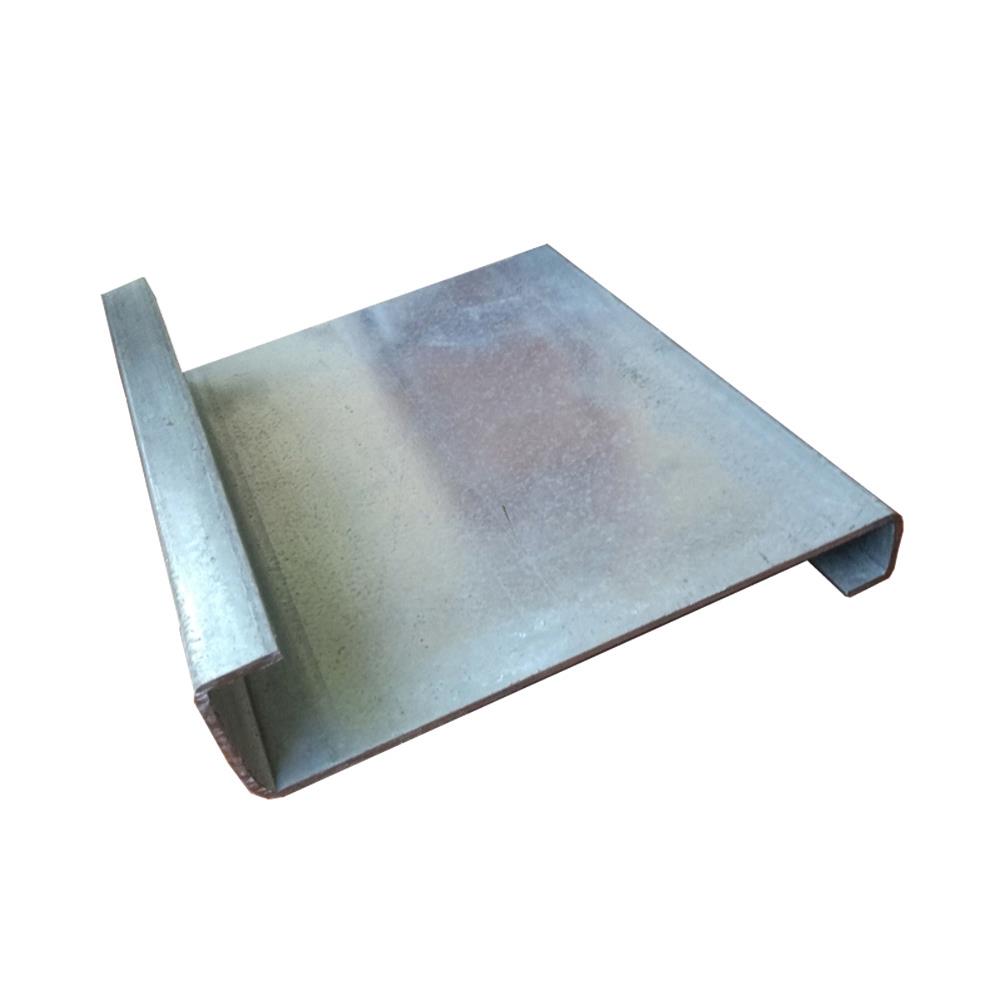

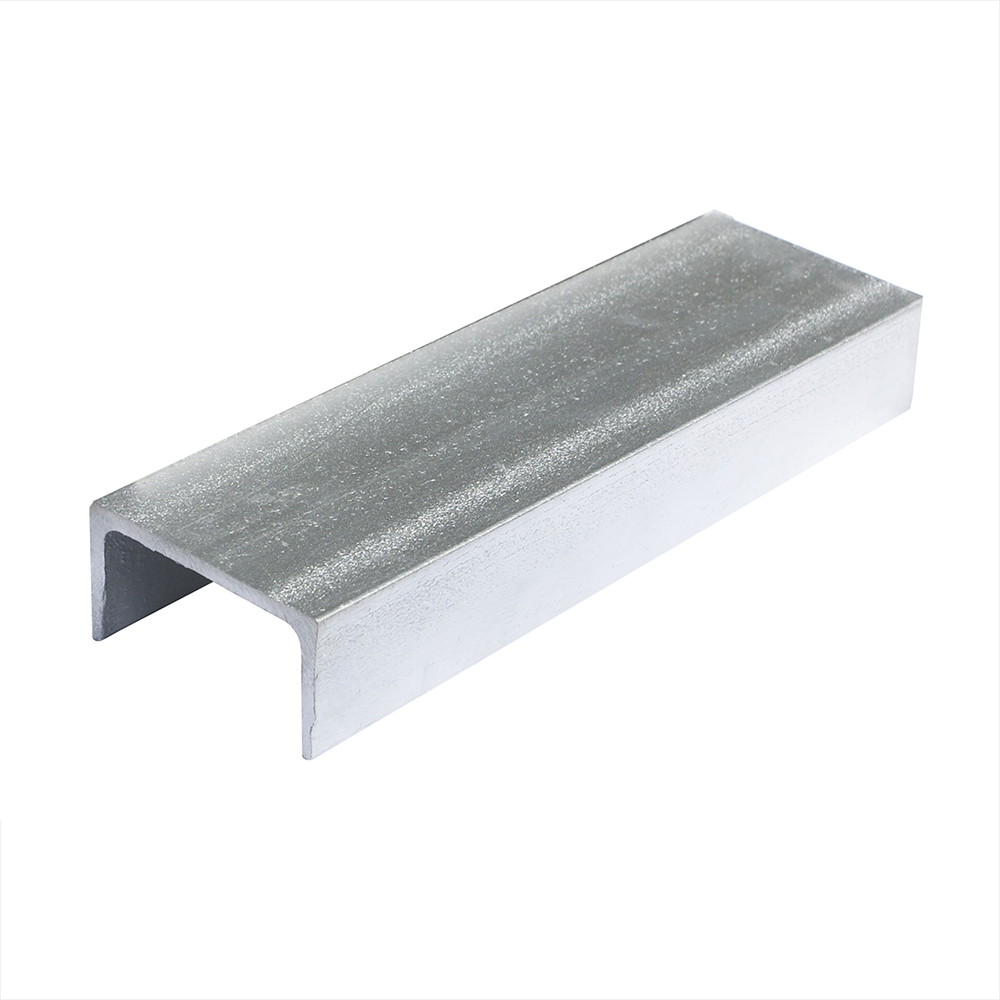

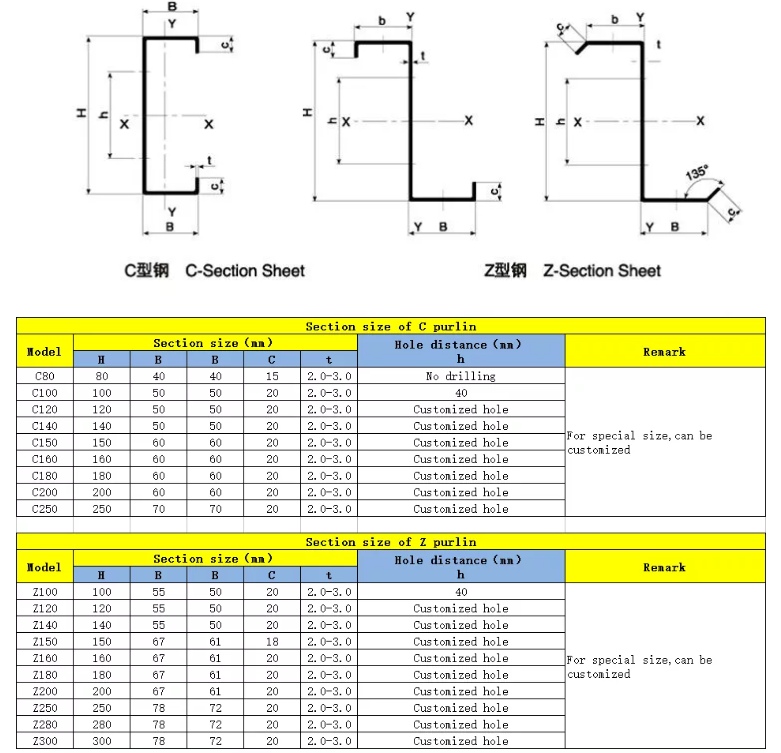

One of the outstanding features of Z-Steel is its versatility. The thickness range is from 1.5mm to 8.0mm, and the section height is from 40mm to 350mm, which can be customized according to your specific requirements. This flexibility makes Z-Steel ideally suited for large steel mills, where hot-rolled and galvanized steel strip is often processed. The Z-Steel is easily adjustable in machining length and hole size for seamless integration into any project.

The applications for Z-beams are nearly endless. Whether you're building doors, windows, or shipping vehicles, Z-Steel is the trusted choice. Its exceptional strength and durability also make it ideal for shelving, electrical cabinets and highway barriers. Additionally, Z-Steel is an excellent choice for building steel structures, containers and scaffolding. Its adaptability further extends to solar support, shipbuilding and bridge construction, among others. With Z-Steel, you can rest assured that your projects will benefit from a material that provides reliability, stability and longevity.

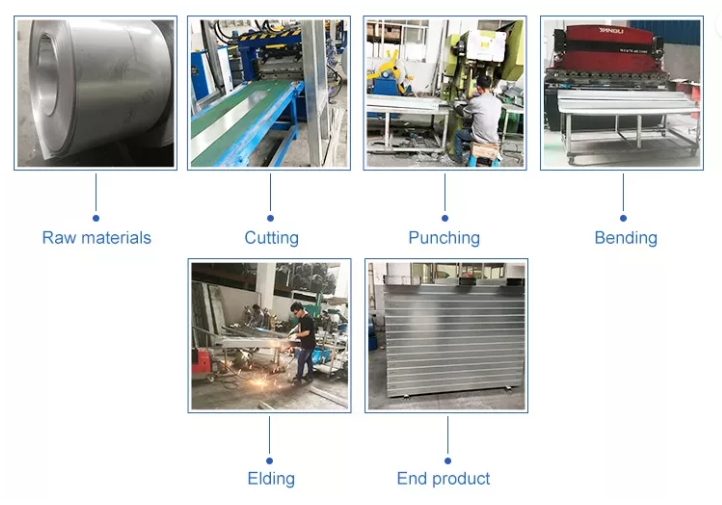

When it comes to quality, Z-Steel sets high standards. Adjustable sizes and high compressive strength ensure your projects are supported by materials that meet all necessary criteria. Designed to stand the test of time, Z-Steel is not only resilient, but also corrosion and impact resistant. Its efficient design and manufacturing process make Z-Steel a cost-effective choice for any construction project. You can trust Z-Steel to deliver superior performance while staying within your budget.

In conclusion, if your steel structure project requires a versatile and reliable solution, Z-Steel is your best choice. Due to its adjustable size, excellent compressive strength and wide range of applications, Z-shaped steel has become the first choice for various industries. Its adaptability coupled with exceptional quality and durability ensures your projects are completed to the highest standard. Don't compromise on the quality of steel construction - choose Z-Steel and experience the difference it can make.