Cold Form C Channel Steel - Steel Fabricated C Z U – Rainbow

Cold Form C Channel Steel - Steel Fabricated C Z U – Rainbow Detail:

Products Introduction

1)Material: Q195,Q235,Q345,SS400,A36 or ST37-2

2)Surface Treatment:Galvanized, Paint, Black mild channel bar.

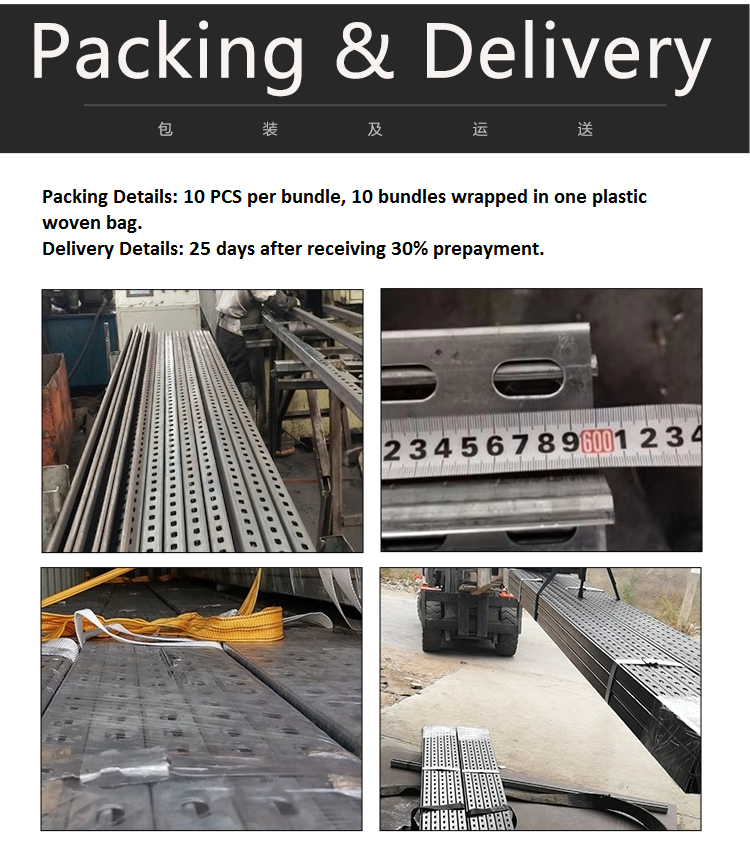

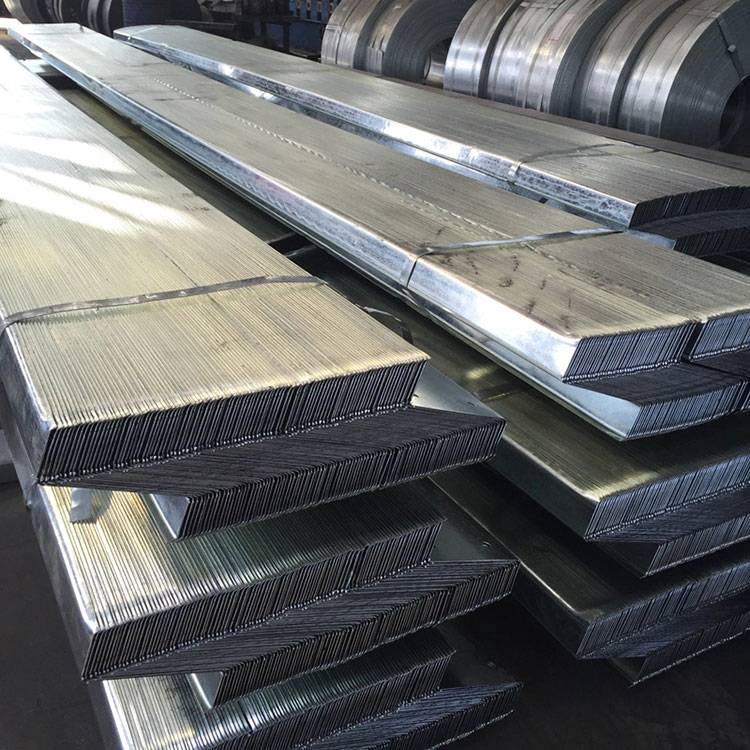

3)Packing:In bundle, as customer specific requirements

4)Application: modern industrial plant, agricultural greenhouse, animal husbandry factory, stockroom-style supermarket, car showroom, sports venue, quay shed, power plant steel structure, airport facility, construction industry,?automobile industry, solar power station, machine manufacturing, steel pylons, ship bridge, military aft industry, highway construction, machine room equipment container, mineral product holder, etc.

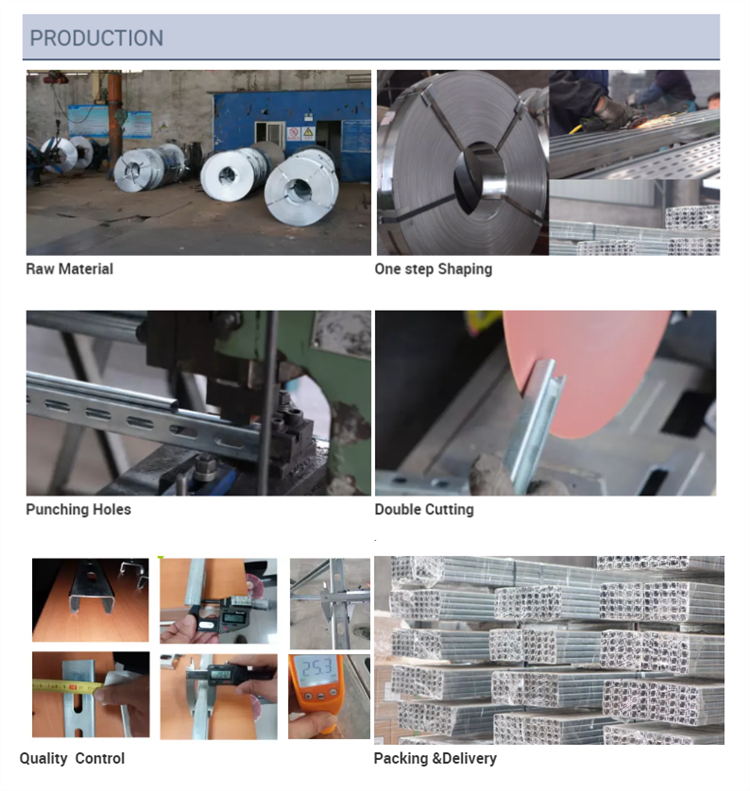

What are the production processes of cold rolled steel channel C Z U?

The production process of cold-rolled strip mills mainly controls billet preparation, pickling, cold rolling, annealing and finishing.

The blank preparation requires chemical composition, width and thickness scales (three-point difference and same line difference), and the sickle bend should meet the requirements, and the surface should be smooth and free of cracks, folds, delamination, pores, non-metallic inclusions, etc.

Strip steel should be straightened and butt welded before pickling for successive pickling. The main purpose of pickling is to get rid of iron oxide scale. During the pickling process, the concentration and temperature of the acid solution and the content of ferrous salt in the acid solution should be controlled.

In order to control the thickness and plate shape, the reduction, speed, tension and roll shape should be adjusted. The thickness is mainly controlled by AGC, and the shape of the plate is mainly controlled by adjusting the roll profile (roll crown and crown compensation method), such as HC, CVC, etc.

Annealing is divided into center annealing and finish annealing. Center annealing is to eliminate work hardening, and product annealing is to obtain the required structure and function. Annealing furnaces include successive annealing furnaces and bell-type annealing furnaces. The annealing process of the bell-type annealing furnace should control the proportion of the protective gas in the furnace, the heating time, and the cooling time; the annealing process of the successive annealing furnace should control the temperature, speed, time and atmosphere according to the annealing curve. Control the strip tension in the furnace to ensure the plate shape, and control the furnace roll crown to avoid strip deviation.

Finishing includes flattening, cutting, oiling and packaging. Flatness can improve the shape of the plate, clean the surface and get the required functions. The flattening process should control the elongation of the strip, and the shearing should mainly control the scale and surface quality, the oil should be uniform, and the packaging should meet the specified requirements, which is conducive to storage, transportation and delivery.

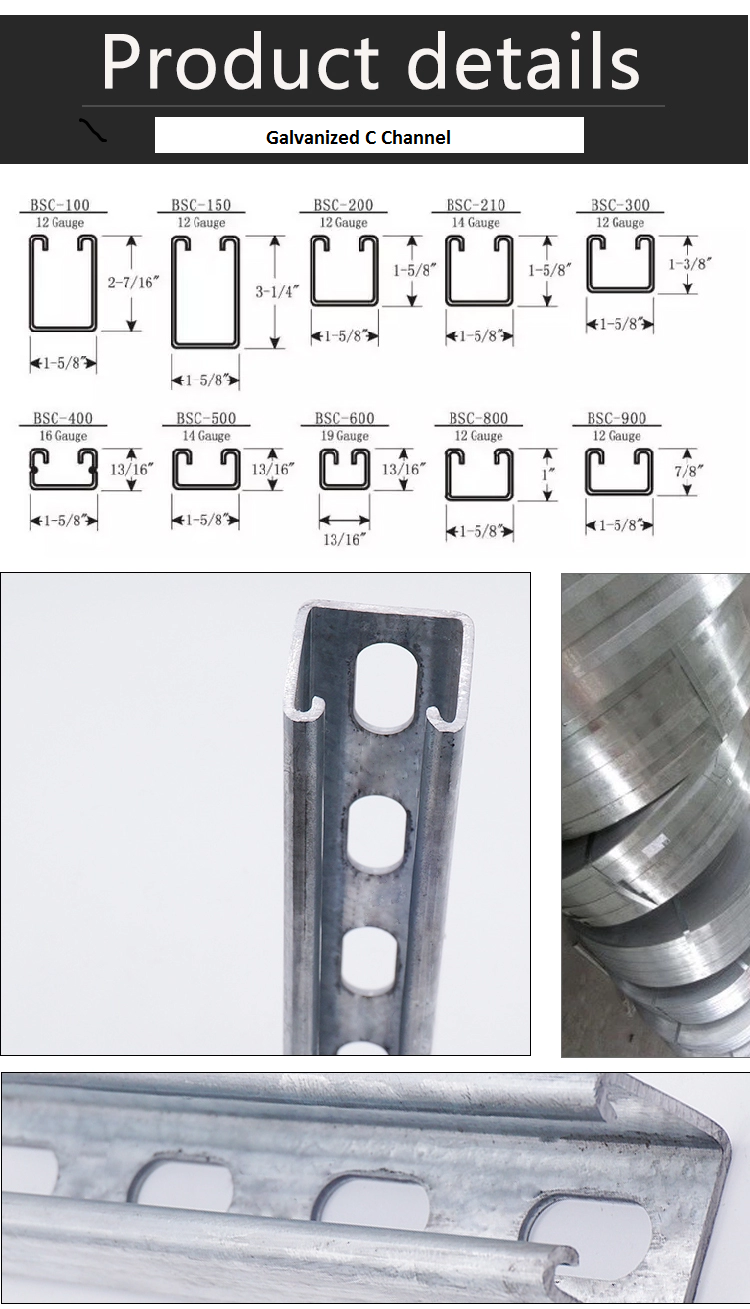

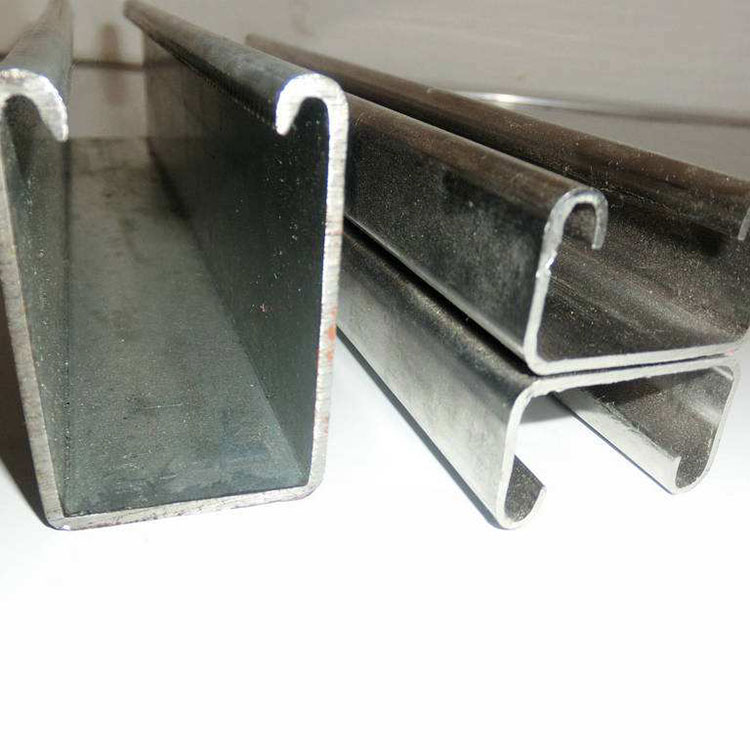

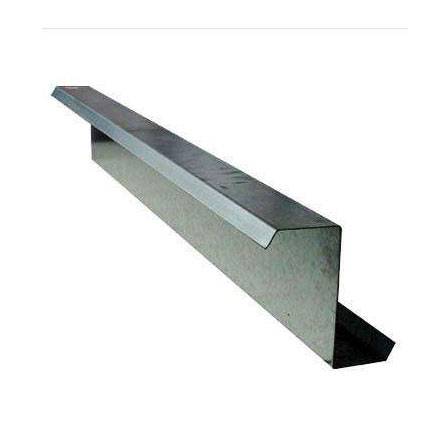

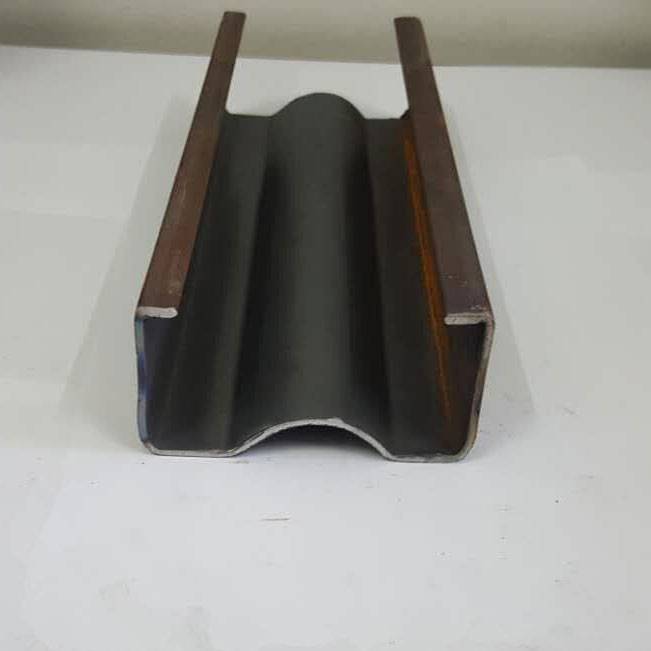

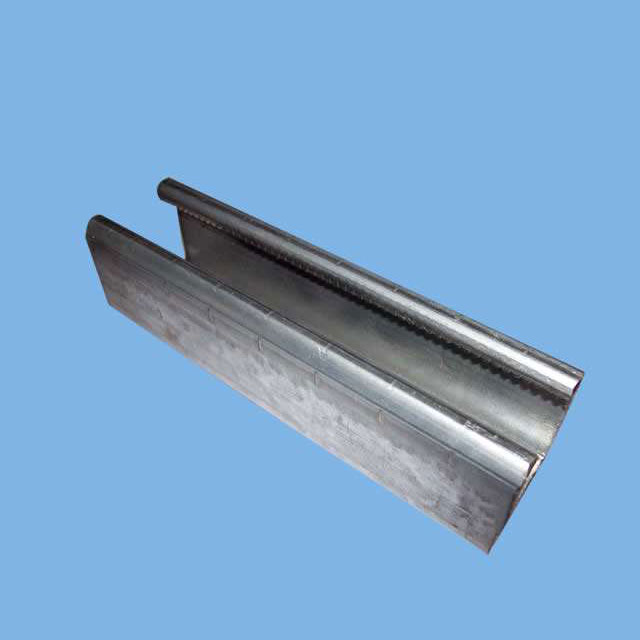

C Channel

Definition:

C Channel is processed automatically by C-steel make-up machine, which, according to given C-steel sizes, can automatically complete the C- steel forming process

Main Application:

C-steel is widely used for purline and wall beam of structural steel construction, and is applicable for combining into roof truss and bracket. In addition, it is also used as columns, bridges and arms in machinery light industry manufacture.

|

Type |

Spec. |

Thickness |

Material |

Surface Treatment |

Punching |

Length |

|

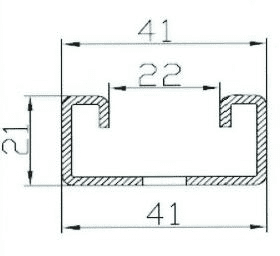

C41*21 |

1.5/2.0mm |

Q235B/Q345B |

Hot dip galvanized 65-80um |

9*30/11*30/13.5*30 |

As customer |

Product detail pictures:

Related Product Guide:

Steel Deep Processing

Fire protection measures for steel structures

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for Cold Form C Channel Steel - Steel Fabricated C Z U – Rainbow , The product will supply to all over the world, such as: Houston, Islamabad, Paris, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.