1. Low treatment cost: The cost of hot dip galvanizing is lower than that of other paint coatings.

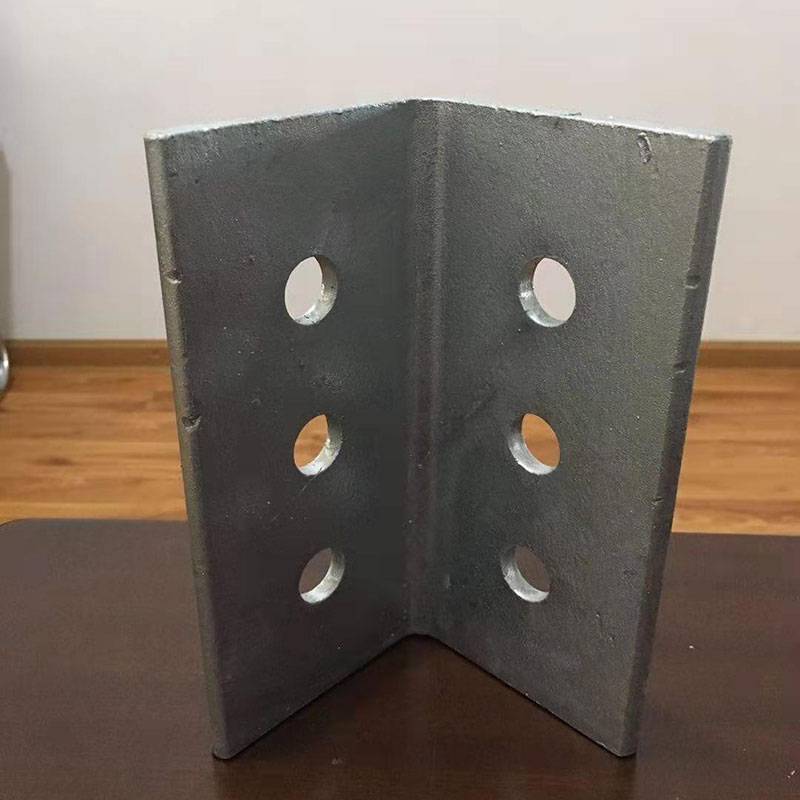

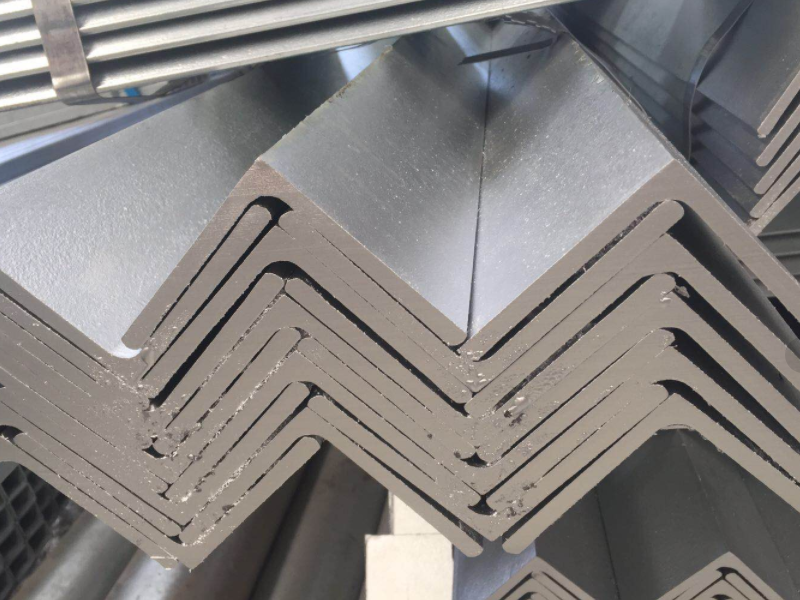

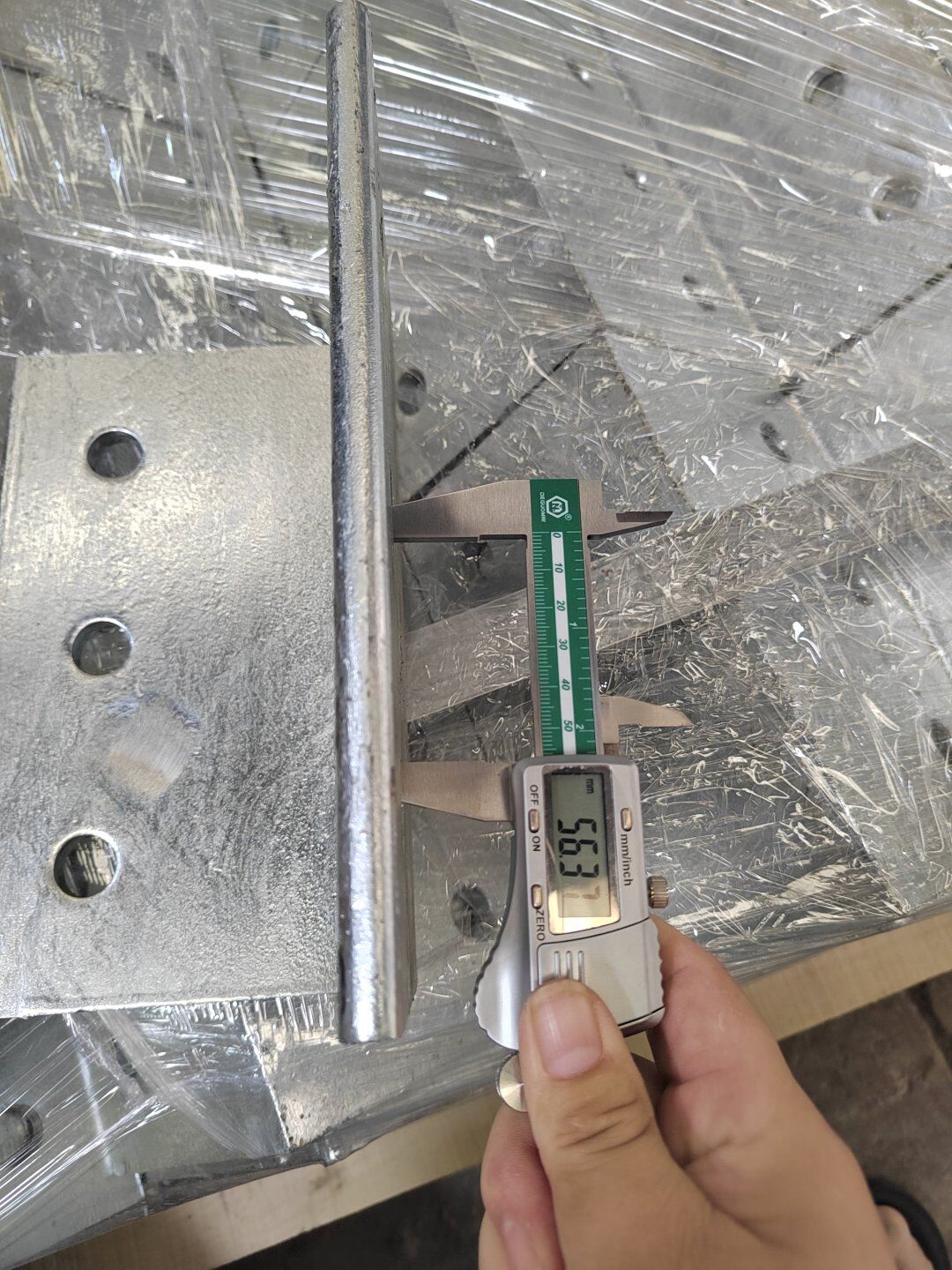

2. Durable: Hot-dip galvanized steel angle iron has the characteristics of surface luster, uniform zinc layer, no leakage, no drip-slip, strong adhesion and strong corrosion resistance. In suburban environment, the standard thickness of hot-dip galvanized rust-proof can be maintained for more than 50 years without repair; in urban or offshore areas, the standard thickness of hot-dip galvanized rust-proof layer can be maintained for 20 years. It doesn’t need to be repaired.

3. Good reliability: The galvanized layer is metallurgical bond with the steel and becomes a part of the steel surface, so the durability of the coating is more reliable.

4. The coating has strong toughness: the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

5. Comprehensive protection: Every part of the plated part can be galvanized, even in the depression, sharp corner and hidden place can be fully protected;

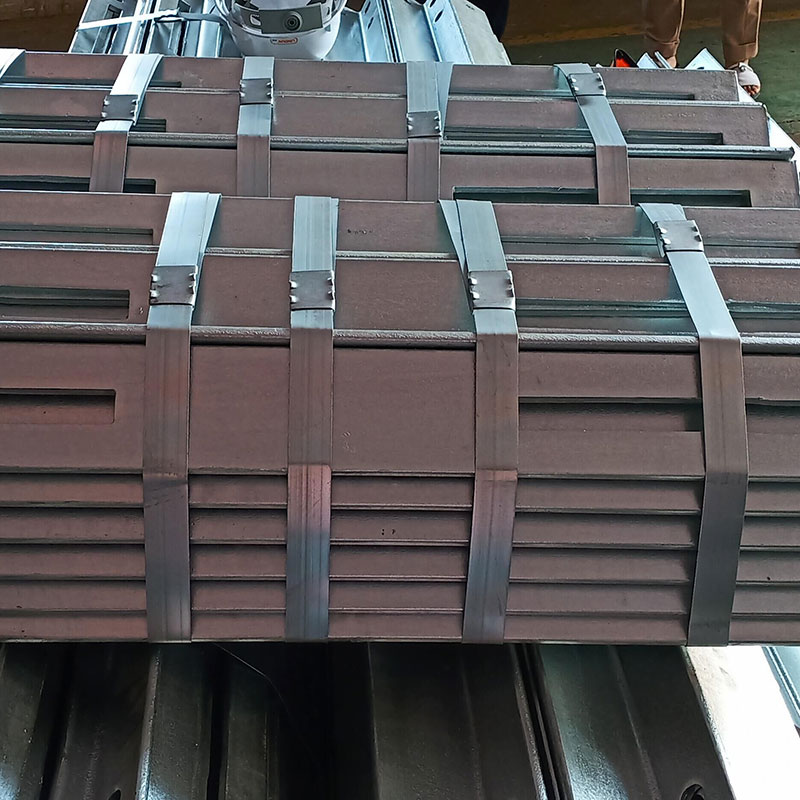

6. Time-saving and labor-saving: galvanizing process is faster than other coating construction methods, and can avoid the time required for painting on the site after installation.