Longitudinal Seam Submerged Arc Welded Steel Pipe - Precision Process on Steel-I Beam with punched holes – Rainbow

Longitudinal Seam Submerged Arc Welded Steel Pipe - Precision Process on Steel-I Beam with punched holes – Rainbow Detail:

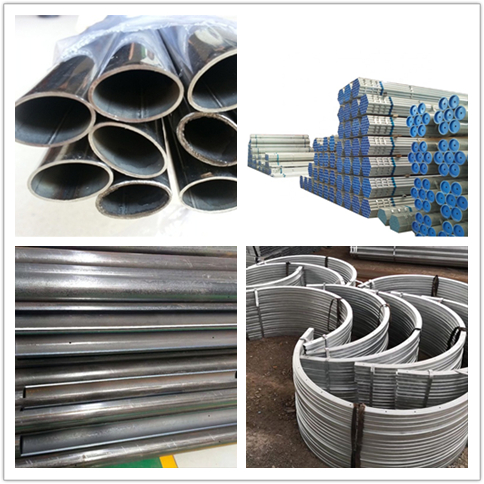

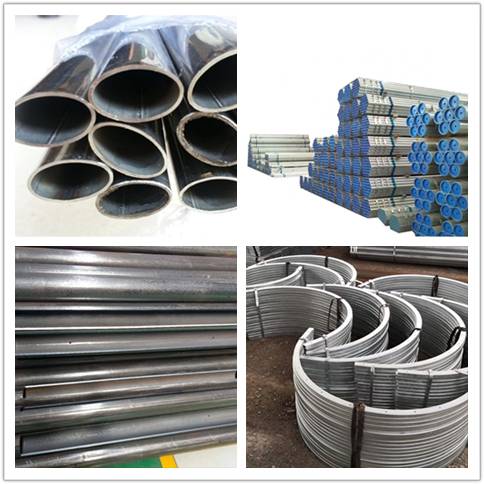

Deep processing of iron and steel is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

We can do kinds of precision process on steel.

- Beveled End

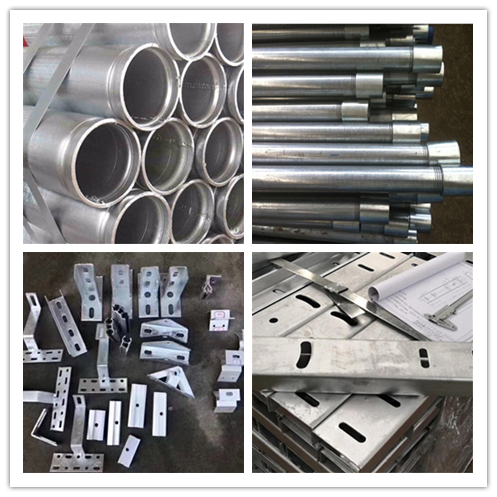

- Steel Cap

- Swage n’ Hole

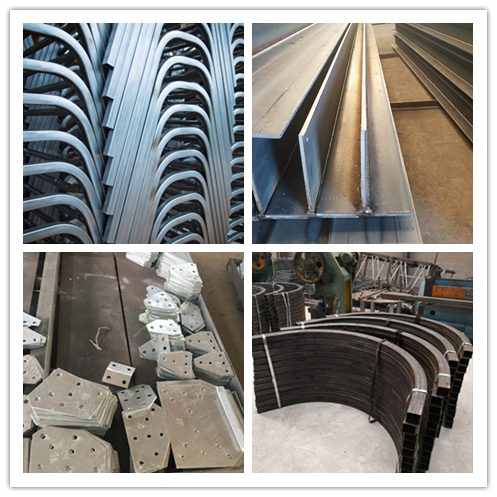

- Bending n’ Punching hole

- Making Groove

- Threading n’ Coupling

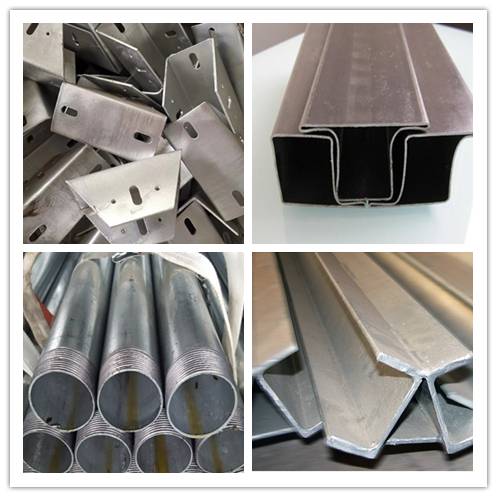

- Welded Part for Solar Mounting System

- Galvanized U Attachment for Ground Mounting

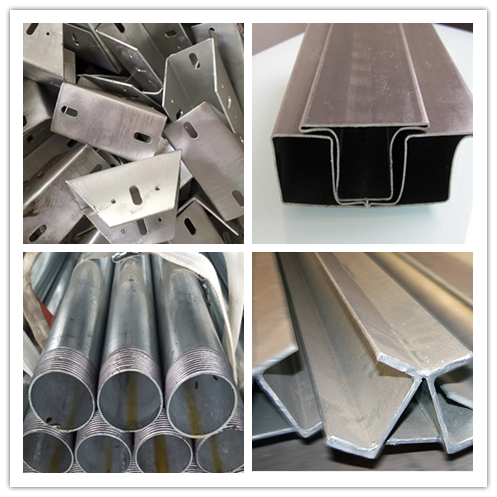

- Steel Pipe Flattening & Holing

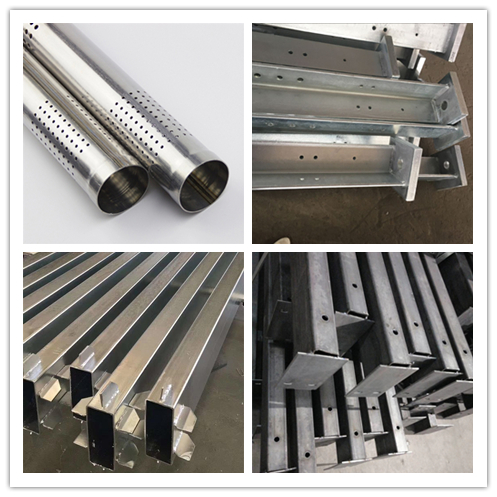

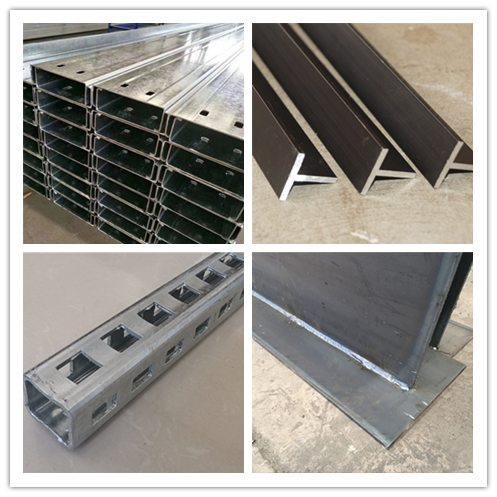

- C Channel with Welded Part

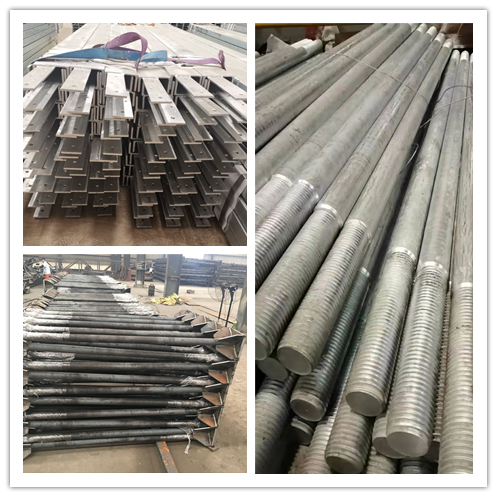

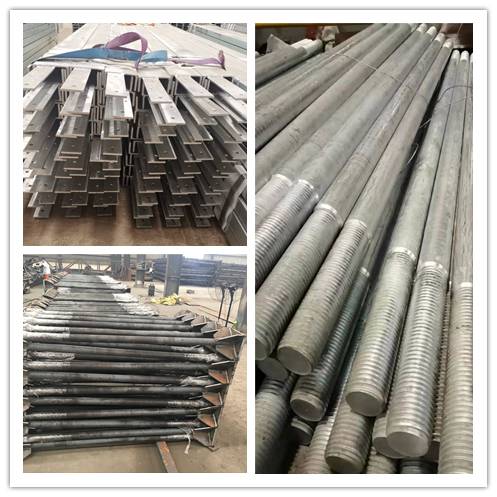

- Galvanized Anchor Bolt From Steel Round Bar

- Anchor Bolt by Pipe Welded Plate

- Holing on steel pipe

- Steel Angle Bar with Punched Hole and Welding Plate

- Welding on Steel Pipe

- I beam with Punched Holes

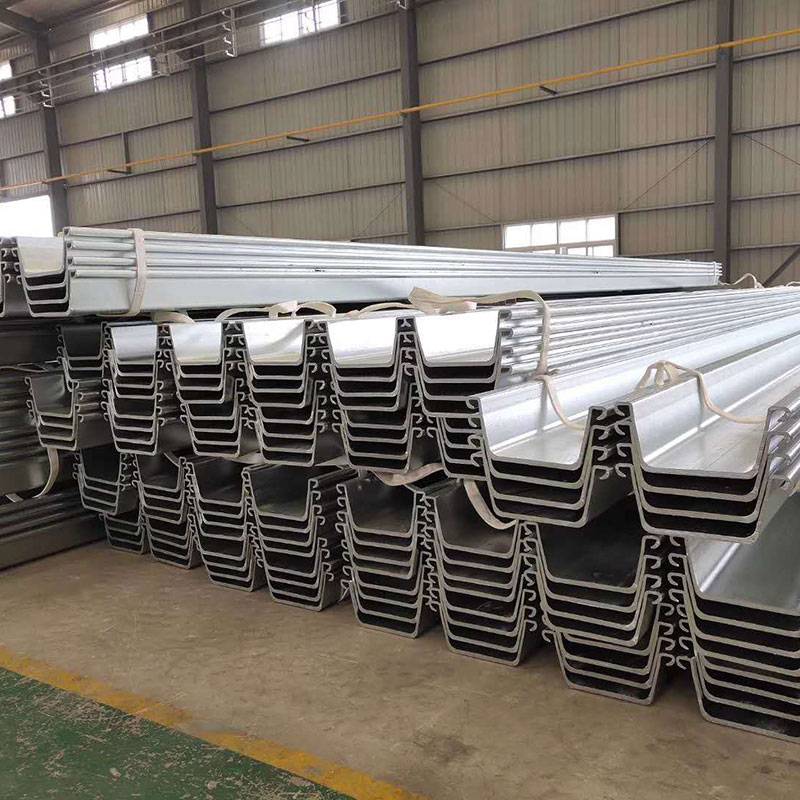

- Cold Formed Galvanized Beam

- Galvanized Steel T Bar or T Lintels

- Changed from Round Pipe, Then Laser Holing

- Submerged ARC Welding

- Welded C Channel

- Iron Angle Holing & Cutting

- Plasma NC Cutting Steel Plate

- C Channel with Welded Legs

Product detail pictures:

Related Product Guide:

Steel Deep Processing

4 kinds of methods of steel structure interlayer

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Longitudinal Seam Submerged Arc Welded Steel Pipe - Precision Process on Steel-I Beam with punched holes – Rainbow , The product will supply to all over the world, such as: Estonia, Madras, Jakarta, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Write your message here and send it to us