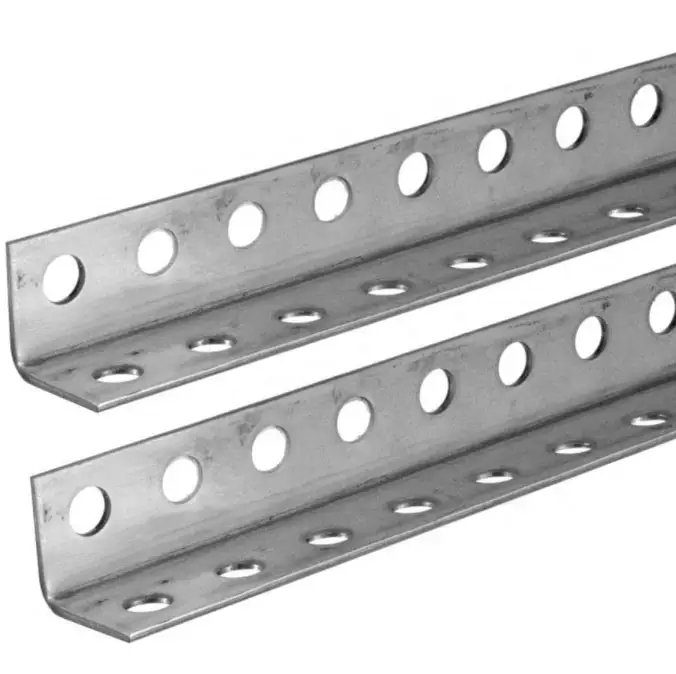

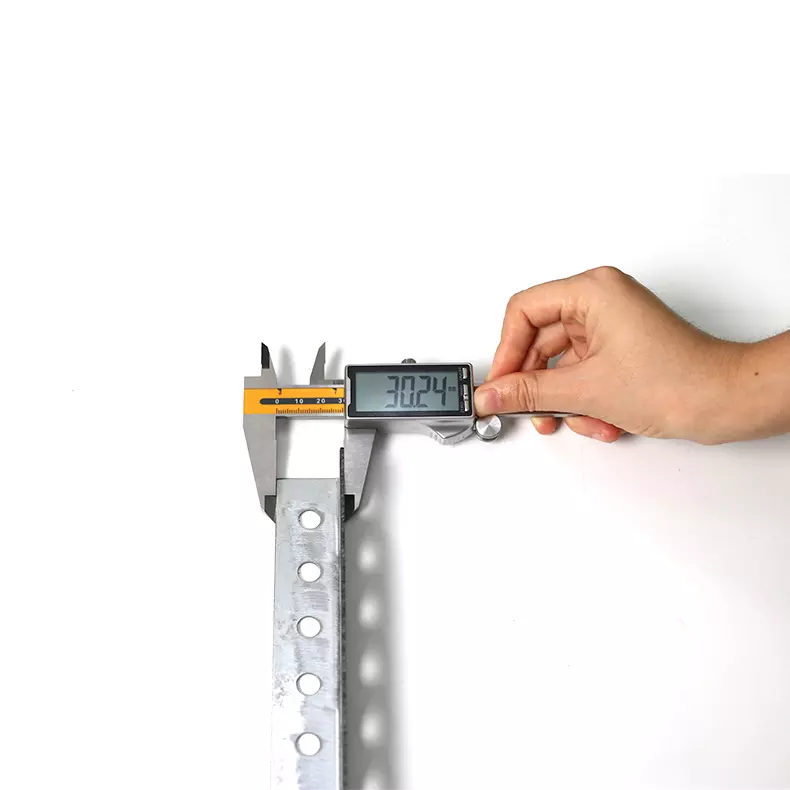

Precision Process on Steel-Angle Bar with welded parts

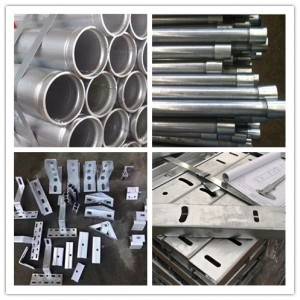

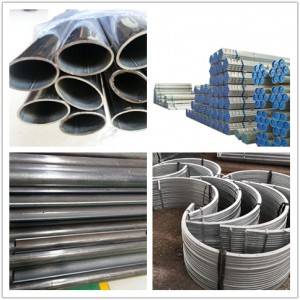

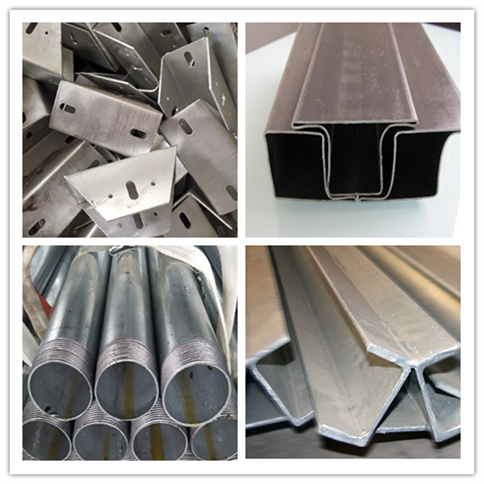

Steel deep processing and iron is to process all kinds of raw steel plates, pipes and wires into products that can be directly used by users by cutting, straightening, flattening, pressing, hot rolling, cold rolling, stamping and other production processes.

Write your message here and send it to us