Galvanized Cuplock Scaffolding Accessories Top Cup Bottom Cup

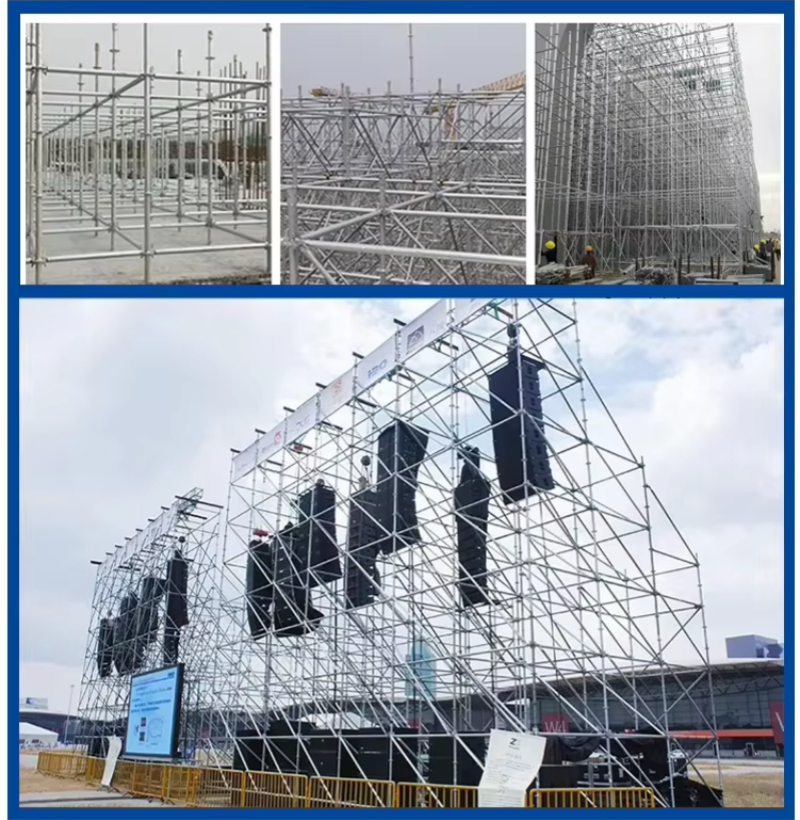

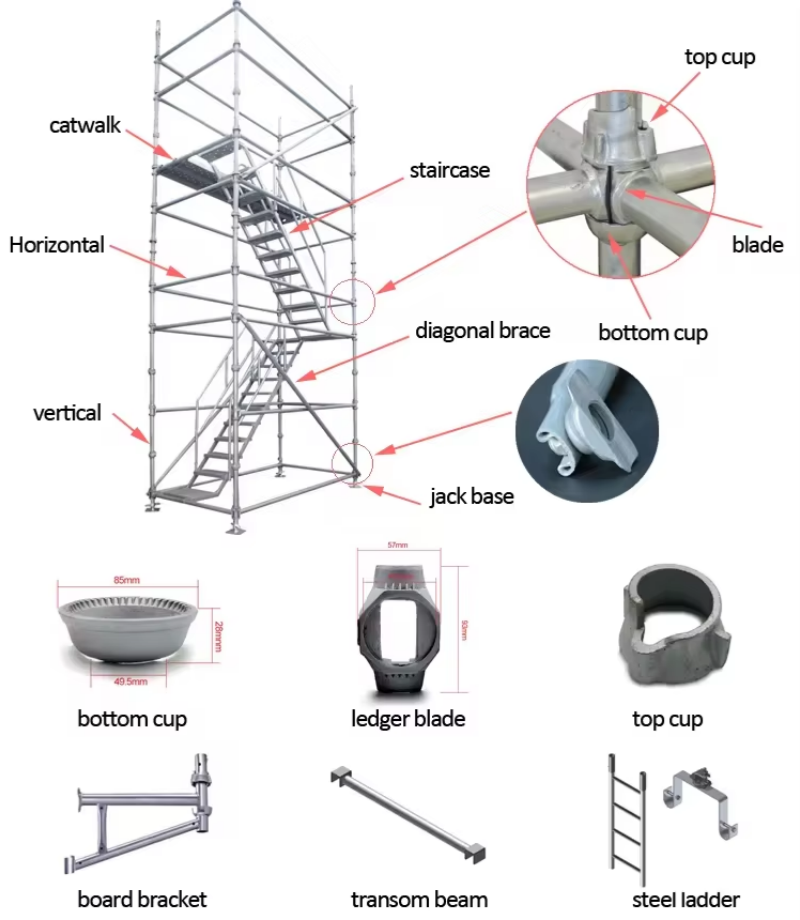

Cuplock scaffolding system is mainly used in Middile East construction market,it has characteristic of low cost and easy assembling. The mainly parts are top cup,bottom cup and wedge. Cuplock scaffolding top cup has two type,one is made by nodular cast iron technology,and follow the sdandard of QT450-10. Another one is made by forging ,use material #20-#30 steel. The bottom cup is made by pressing with material Q235,and wedge normally made by forging also. Cuplock scaffolding system include:Vertical tube,Horizontal tube,Diagonal brace,Staircase,Catwalk,Jack base,U-head and with other accessories,Widely used in bridge,building construction. It's very safety and efficient. People usually weld the bottom cup to the vertical support , one pc for every 600mm ; the ledger head is also welded to the horizontal support and will be inserted into the bottom cup during installation. The top cup is removable and used to fixed the ledger head on top. These cuplock accessories are easy to use and save, one worker could assemble the cuplock scaffolding easily.

Cuplock scaffolding is a unique node point connection allows up to four horizontal members to be connected to a veritical members in one single action without the use of nuts and bolts or wedges. The locking device is formed by two cups. Single node point action of unique locking make cuplock scaffold a fast, versatile and optimized system of scaffolding for scaffolding for construction, demolition and maintenance projects throughout the globe.

Top cup

Size: 48mm

Weight: 200g/240g/250g

Thickness: 4mm/4.5mm/5mm

Surface: Hot Dipped Galvnazied/self color/painted

Application: Scaffolding Supporting Parts

Bottom cup

Material: Q235

Size : OD48.3mm

Surface treatment: Galvanized/self color/painted

Packaging: in weaving bags or Wooden case

Application: Suit for cup lock scaffolding

|

1. Easy to stand. Just a simple locking cup at each node point on the standards enables connection of the ends of up to four members in one locking action without nuts and bolts or wedges.

2. Versatile. Best suitable for access or formwork support.

3. Timely tested and Proven design with safety accessories. Cuplock System has a proven performance history on an extensive number of sites, meeting the requirements of the various statutory bodies.

4. Quick fastening of horizontals. Only 4 horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid.

5. Quick/Fast/Solid erection and dismantling results in time and labour saving.

6. Widely and Versatile use in construction, demolition or maintenance projects for any type of structure i.e. straight or curved.

7. Lightweight but high loads carrying capacity.

8. Low maintenance.

* Quick erection, less time and effort: Maximum standard weight reaches 17.07kg, the erection and disassembly rate 3-5 times faster than the conventional scaffolding.

* High capacity load: stable and reliable structure with outstanding performance; the joint connector of cuplock can resist high bending, shearing and torsion, with load capacity 15% more than traditional tubular &fitting scaffolding system.

* Safe and reliable: Three-dimension axial force express and structure of the scaffold can create high strength, good stability and perfect auto-lock and meet the requirement of safe construction.

* Maintenance &management free-trouble: No loose accessories, complete system easy to manage during.

Tianjin Rainbow Steel Group, a professional manufacturer and supplier in China, manufacturing steel products and structure fortheSolar Mounting System.

We hold the newest advanced machines and the best manufacturing skills, and a strict quality control system with a complete set ofupdated devices for testing and inspection from raw material out sourcing to cargo delivery. We got the certificate of BV and ISO9001:2000, products can meet ASTM DIN JIS GB BS standards for different markets.

Our products have spread all over the world, such as Australia, North America, South America, Southeast Asia, European countries like Germany, Italy, Asia like India and UAE, etc.

"Winning by Quality, Winning by Service", welcome to Tianjin Rainbow Steel.

1. who are we?

We are based in Tianjin,China,start from 2014,sell to Oceania(45.00%),Mid East(13.00%),Mid East(13.00%),Eastern Asia(8.00%),South Asia(8.00%),Eastern Asia(8.00%),Central America(6.00%),Southeast Asia(6.00%),South America(6.00%),Central America(6.00%),Southeast Asia(6.00%),Northern Europe(5.00%),Northern Europe(5.00%),Africa(3.00%),Africa(3.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Props, Scaffoldings, Scaffolding Accessories, Formwork, Formwork Accessories;

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards;

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese