Gi Pipe - Spiral Submerged Arc Welding Pipe (SSAW) – Rainbow

Gi Pipe - Spiral Submerged Arc Welding Pipe (SSAW) – Rainbow Detail:

Welded steel pipes with hot dip coating or electric-galvanized?coating on the surface of galvanized steel pipes. Galvanizing can? increase the corrosion resistance of steel pipes and prolong their service life. Galvanized pipes are widely used, not only as pipelines for water, gas, oil and other general low-pressure fluids, but also as oil well pipes and oil pipelines in the petroleum? industry, especially in offshore oil fields, oil heaters, condensation coolers, tubes for coal distillation and washing oil?exchangers in chemical coking equipment, and tubes for trestle pipe piles and support frames in mine tunnels.

| Secondary or not | Non-secondary |

| Alloy or not | Non-alloy |

| Technique | ERW, hot rolled or cold rolled |

| Standard | BS 1387, BS EN 39, GB/T 3091, ASTM A53, JIS G3444, etc. |

| Grade/Material | 10#, 20#, 45#, Q195, Q235, Q345, 16Mn, ST 37.4, etc. |

| Place of origin | Tianjin, China(Mainland) |

| Certifications | ISO 9001:2008, BV, SGS, ABS |

| Production capacity | 3500 ton/week |

| Section shape | Round |

| Outer diameter | 20-325mm |

| Wall thickness | 0.5-25mm |

| Length | 2-12m, or cut as request. |

| Technique tolerance | OD: +/-1mm, WT: +/-0.5mm, L: +/-20mm |

| Surface treatment | Galvanized, painted, oiled, printed or powder coated |

| Zinc coated | pre-galvanized, 80-120 g/m2; hot dip galvanized, 230-500 g/m2 |

| Colour | Silver, black or painted as request |

| End of pipe | Plain?burred,beveled, threaded |

| Trade term | FOB Tianjin China, CIF, C&F |

| Loading Port | Tianjin Xingang Port, China |

| Package | 1.Big OD: in bulk; 2.Small OD: in bundles, packed by steel strips; 3. Waterproof package with plastic cloth; 4.Standard export package; 5.According to customers |

We have great technical capability, advanced production equipment, complete testing equipment. We introduced the international leading American Lincoln welding machine, the automatic welding laser tracking system (import from England0, hydro-static testing machine, X-ray, ultrasonic, expanding equipment (bell and spigot) and spectrograph (import from Japan ), drop-testing, impact(300 Joules with minus 60 degrees Celsius), hardness testing, metallurgical microscopy equipment etc .

Our products are wildly used in Petrileum and natural gas pipelines, Heating and water supply. Waste water treatment, Chemical industry. Steel structure, Bridge, Piling, Sea port and Electric power industry. We ca produce the SSAW pipe under the API 5L, ASTM A252, GB/T9711.1, GB/T9711.2 standard and under the clients requirements with the steel grade: Gr, A, Gr, B, X42, X100, L245-L485, S290 and above, SS400 and above, ST33, ST42, Q235 (A,B,C), Q345 (B,C,D,R) etc.

Commonly used double-sided submerged arc spiral welded pipe specifications, kg/m

|

Item No. |

Specifications |

Kg per M |

Item No. |

Specifications |

Kg per M |

Item No. |

Specifications |

Kg per M |

|

1 |

219*6 |

32.02 |

30 |

529*9 |

115.92 |

59 |

920*9 |

202.70 |

|

2 |

219*7 |

37.10 |

31 |

529*10 |

128.94 |

60 |

920*10 |

24.92 |

|

3 |

219*8 |

42.13 |

32 |

529*11 |

141.02 |

61 |

920*11 |

247.09 |

|

4 |

273*6 |

40.01 |

33 |

529*12 |

153.50 |

62 |

920*12 |

269.21 |

|

5 |

273*7 |

46.42 |

34 |

529*13 |

165.93 |

63 |

920*13 |

291.28 |

|

6 |

273*8 |

52.78 |

35 |

630*6 |

92.83 |

64 |

1020*8 |

200.16 |

|

7 |

325*6 |

47.70 |

36 |

630*7 |

108.05 |

65 |

1020*9 |

224.89 |

|

8 |

325*7 |

55.40 |

37 |

630*8 |

123.22 |

66 |

1020*10 |

249.58 |

|

9 |

325*8 |

63.04 |

38 |

630*9 |

138.33 |

67 |

1020*11 |

274.22 |

|

10 |

377*6 |

55.40 |

39 |

630*10 |

153.40 |

68 |

1020*12 |

298.81 |

|

11 |

377*7 |

64.37 |

40 |

630*11 |

168.42 |

69 |

1020*13 |

323.34 |

|

12 |

377*8 |

73.30 |

41 |

630*12 |

183.39 |

70 |

1220*10 |

298.90 |

|

13 |

377*9 |

82.18 |

42 |

630*13 |

198.31 |

71 |

1220*11 |

323.47 |

|

14 |

426*6 |

62.65 |

43 |

720*6 |

106.15 |

72 |

1220*12 |

357.99 |

|

15 |

426*7 |

72.83 |

44 |

720*7 |

123.59 |

73 |

1220*13 |

387.46 |

|

16 |

426*8 |

82.97 |

45 |

720*8 |

140.97 |

74 |

1420*12 |

417.18 |

|

17 |

426*9 |

93.05 |

46 |

720*9 |

158.31 |

75 |

1420*14 |

485.94 |

|

18 |

426*10 |

103.09 |

47 |

720*10 |

175.60 |

76 |

1520*12 |

446.77 |

|

19 |

478*6 |

70.34 |

48 |

720*11 |

192084.00 |

77 |

1520*14 |

520.46 |

|

20 |

478*7 |

81.81 |

49 |

720*12 |

210.02 |

78 |

1720*12 |

505.96 |

|

21 |

478*8 |

92.23 |

50 |

720*13 |

227.16 |

79 |

1720*14 |

589.52 |

|

22 |

478*9 |

104.60 |

51 |

820*7 |

140.85 |

80 |

1820*12 |

535.56 |

|

23 |

478*10 |

115.92 |

52 |

820*8 |

160.70 |

81 |

1820*14 |

624.04 |

|

24 |

478*11 |

127.19 |

53 |

820*9 |

180.50 |

82 |

1920*12 |

565.15 |

|

25 |

478*12 |

138.41 |

54 |

820*10 |

200.26 |

83 |

1920*14 |

658.57 |

|

26 |

478*13 |

149.58 |

55 |

820*11 |

219.96 |

84 |

2020*12 |

594.74 |

|

27 |

529*6 |

77.89 |

56 |

820*12 |

239.62 |

85 |

2020*14 |

693.09 |

|

28 |

529*7 |

90.61 |

57 |

820*13 |

259.22 |

86 |

2020*16 |

791.25 |

|

29 |

529*8 |

103.29 |

58 |

920*8 |

180.43 |

87 |

2020*18 |

889.20 |

Remark: We can produce per customer’s technical requirements

| Standard of Products | ||

| Standard Serial No. | Standard Name | Type of Products |

| API-5L PSL 1.2 |

Line Pipes Standard | Spira-seam steel pipes; Longitudinal-seam submerged arc steel pipes; High Frequency Longitudinal-seam steel pipes |

| GB/T9711-2011 PSL1 PSL2 |

The first Part of Oil-Gas industrial Transportation Steel Pipes Consinment Technical Qualification level A Steel Pipes | Spiral-seam Steel Pipes |

| SY/T5037-2000 | Spiral-seam Submerged arc steel pipes use for Low-pressure Liquid Transportation Pipeline | Spiral-seam Steel Pipes |

| GB/T14980-94 | Wide-diemetric Electric welded Steel pipes used for Low-pressure Liquid Transportation Pipeline | High Frequency Longitudinal-seam Steel Pipes |

| GB/T3091-2008 | Electric Welded Steel Pipes used for Low-pressure Liquid Transportation Pipe | High Frequency Longitudinal-seam Steel Pipes |

| GB/T13793-92 | longitudinal-seam Electric Welding Steel Pipes | High Frequency Longitudinal-seam Steel pipes |

| GB/T5384-91 | Longitudinal-seam Resistance Welding Steel Pipes used for Common Liquid Transportation Pipelines | High Frequency Longitudinal-seam Steel Pipes |

Remark: We can produce per customer’s technical requirements

| Item No. | Nominal Diameter (mm) | Wall Thickness (mm) | Hydrostatic Test Presure | |||||||

| API Spec 5L | GB/T9711-2011 | SY/T5037-2000 | SY/T5384-91 | |||||||

| Steel Grade | Steel Grade | Steel Grade | Steel Grade | |||||||

| X52 | X60 | Q235 | L360 | Q235 | 16Mn | Q215 | Q235 | |||

| 1 | 219 | 6 | 16.7 | 19.3 | 10.3 | 14.8 | 7.7 | 11.3 | 7.1 | 7.7 |

| 7 | 19.5 | 22.5 | 12.0 | 17.3 | 9.0 | 13.2 | 8.2 | 9.0 | ||

| 8 | 22.3 | 25.7 | 13.7 | 19.7 | 10.3 | 15.1 | 9.4 | 10.3 | ||

| 2 | 273 | 6 | 13.4 | 15.5 | 8.3 | 13.5 | 6.2 | 9.1 | 5.7 | 6.2 |

| 7 | 15.6 | 18.0 | 9.6 | 15.7 | 7.2 | 10.6 | 6.6 | 7.2 | ||

| 8 | 17.9 | 20.6 | 11.0 | 17.9 | 8.3 | 12.1 | 7.6 | 8.3 | ||

| 3 | 325 | 6 | 11.3 | 13.0 | 6.9 | 11.3 | 5.2 | 7.6 | 4.8 | 5.2 |

| 7 | 13.1 | 15.2 | 8.1 | 13.2 | 6.1 | 8.9 | 5.6 | 6.1 | ||

| 8 | 15.0 | 17.3 | 9.3 | 15.1 | 6.9 | 10.2 | 6.4 | 6.9 | ||

| 4 | 377 | 6 | 9.7 | 11.2 | 6.0 | 9.7 | 4.5 | 6.6 | 4.1 | 4.5 |

| 7 | 11.3 | 13.1 | 7.0 | 11.4 | 5.2 | 7.7 | 4.8 | 5.2 | ||

| 8 | 13.0 | 14.9 | 8.0 | 13.0 | 6.0 | 8.8 | 5.5 | 6.0 | ||

| 9 | 14.6 | 16.8 | 9.0 | 14.6 | 6.7 | 9.9 | 6.2 | 6.7 | ||

| 5 | 406.4 | 6 | 9.0 | 10.4 | 5.6 | 9.0 | 4.2 | 6.1 | 3.8 | 4.16 |

| 7 | 10.5 | 12.1 | 6.5 | 10.5 | 4.9 | 7.1 | 4.4 | 4.9 | ||

| 8 | 12.0 | 13.9 | 7.4 | 12.0 | 5.6 | 8.1 | 5.1 | 5.6 | ||

| 9 | 13.5 | 15.6 | 8.3 | 13.6 | 6.2 | 9.2 | 5.7 | 6.2 | ||

| 10 | 15.0 | 17.3 | 9.3 | 15.1 | 6.9 | 10.2 | 6.3 | 6.9 | ||

| 6 | 426 | 6 | 8.6 | 9.9 | 5.3 | 8.6 | 4.0 | 5.8 | 3.6 | 4.0 |

| 7 | 10.0 | 11.6 | 6.2 | 10.1 | 4.6 | 6.8 | 4.2 | 4.6 | ||

| 8 | 11.5 | 13.2 | 7.1 | 11.5 | 5.3 | 7.8 | 4.8 | 5.3 | ||

| 9 | 12.9 | 14.9 | 7.9 | 12.9 | 6.0 | 8.7 | 5.5 | 6.0 | ||

| 10 | 14.3 | 16.5 | 8.8 | 14.4 | 6.6 | 9.7 | 6.1 | 6.6 | ||

| 7 | 478 | 6 | 7.7 | 8.8 | 4.7 | 7.7 | 3.5 | 5.2 | 3.2 | 3.5 |

| 7 | 8.9 | 10.3 | 5.5 | 9.0 | 4.1 | 6.1 | 3.8 | 4.1 | ||

| 8 | 10.2 | 11.8 | 6.3 | 10.2 | 4.7 | 6.9 | 4.3 | 4.7 | ||

| 9 | 11.5 | 13.3 | 7.1 | 11.5 | 5.3 | 7.8 | 4.9 | 5.3 | ||

| 10 | 12.8 | 14.7 | 7.9 | 12.8 | 5.9 | 8.7 | 5.4 | 5.9 | ||

| 8 | 529 | 6 | 7.3 | 8.5 | 4.3 | 7.3 | 3.2 | 4.7 | 2.9 | 3.2 |

| 7 | 8.6 | 9.9 | 5.0 | 8.6 | 3.7 | 5.5 | 3.4 | 3.7 | ||

| 8 | 9.8 | 11.3 | 5.7 | 9.8 | 4.3 | 6.3 | 3.9 | 4.3 | ||

| 9 | 11.0 | 12.7 | 6.4 | 11.0 | 4.8 | 7.0 | 4.4 | 4.8 | ||

| 10 | 12.2 | 14.1 | 7.1 | 12.2 | 5.3 | 7.8 | 4.9 | 5.3 | ||

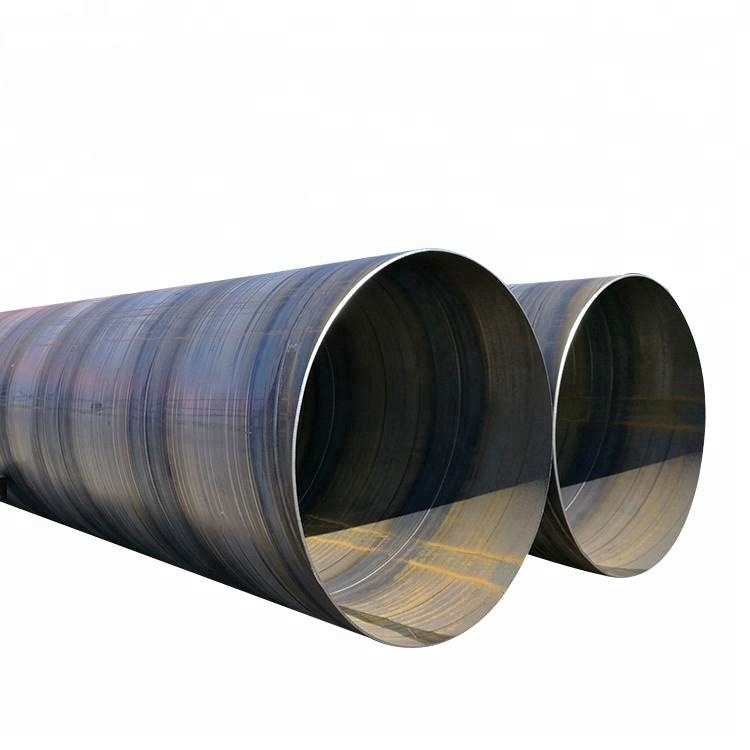

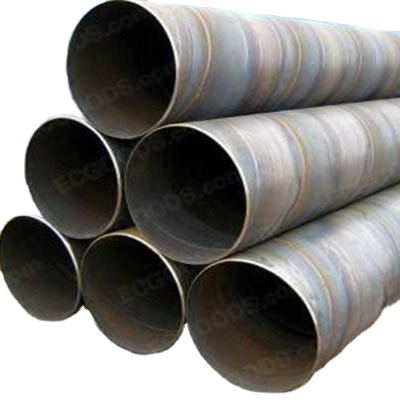

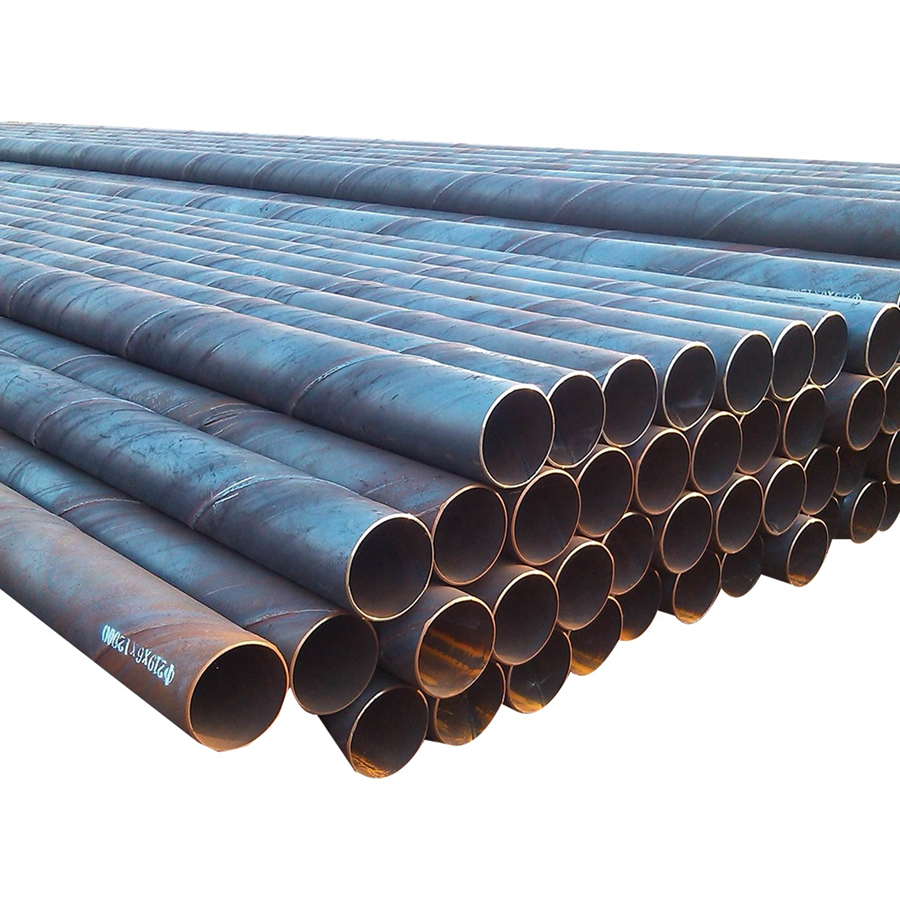

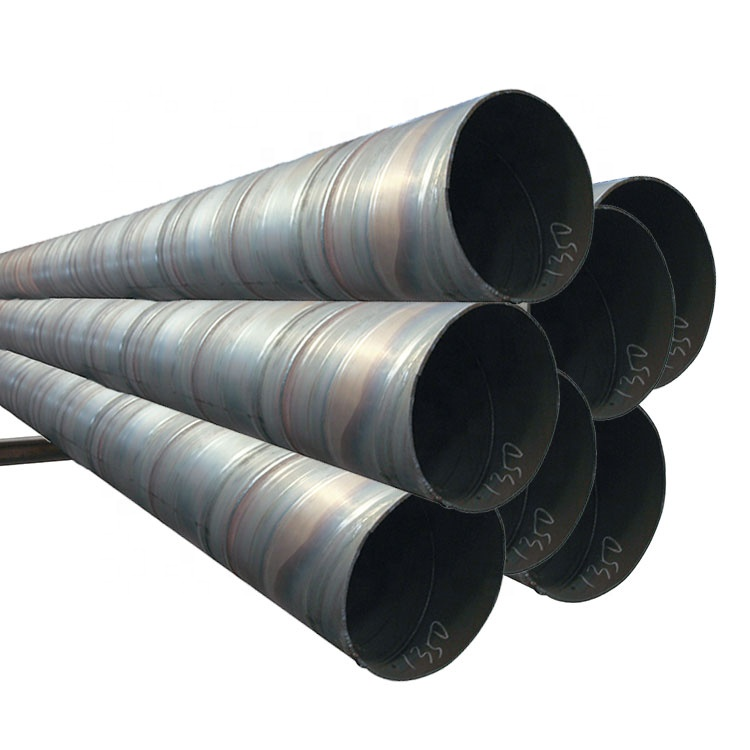

Product detail pictures:

Related Product Guide:

4 kinds of methods of steel structure interlayer

Greenhouse commonly used steel greenhouse introduction

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Gi Pipe - Spiral Submerged Arc Welding Pipe (SSAW) – Rainbow , The product will supply to all over the world, such as: Romania, Estonia, United States, We will supply much better products with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.